Lakhotia India Bucket Elevator Belt: Enhancing Your Vertical Conveying Solutions

Are you looking for a reliable bucket elevator belt for your industrial needs? Look no further than Lakhotia India! Our bucket elevator belts are designed to provide high-performance, durability, and long-lasting solutions for your vertical conveying needs.

Lakhotia India is a leading supplier of bucket elevators that are designed to meet the needs of a variety of industries.

Bucket elevators are an essential piece of equipment for many industries as they enable the efficient movement of materials, reducing manual handling and increasing productivity.

Bucket Elevator Belt Problems?

Slippage on the pulleys can cause the belt to move slowly, resulting in lower efficiency and slower throughput of material.

If the belt isn’t tracking properly, it can cause the material to spill over the edge, resulting in material loss and potential safety hazards.

Wear and tear of the belt can lead to breakage, resulting in downtime and lost production.

Poor belt tension: If the belt is too loose or too tight, it can cause uneven loading, resulting in uneven material flow.

Bucket Elevator Belt

Bucket Elevator | A bucket elevator, also known as a grain leg, is a mechanism used for vertically transporting flowable bulk materials, most commonly grain or fertilizer. Bucket elevators are an essential component of many industries, from mining and agriculture to food and beverage processing. These machines are designed to move materials vertically, making them an important part of any production process. Bucket elevators can use a solivator belt, which is commonly used in the feed and grain industries, or a rubber belt for heavy-duty industrial applications. |

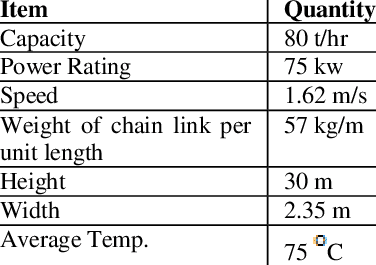

| Bucket Elevator Belt Benefits 1. Easy and quick replacement in case of damaged or worn parts without having to dismount the bucket elevator 2. Easy assembly Reliable operation 3. Smoothly and quickly 4. Minimum of maintenance 5. Low energy consumption 6. Minimized downtime = maximized profit for the end-user 7. Speed 1 to 250 Feet Per Minute 8. Antistatic, oil- and fat resistant, food grade | Bucket Elevator Belt Technical Specification |

Bucket Elevator Belt Design

A bucket elevator consists of buckets attached to a chain or belt that revolves around two pulleys one at top and the other at bottom. The bucket elevator is a very efficient device for the vertical conveyance of bulk grains.

The bucket elevator can lift the materials between few meters to more than 50 m.

Capacities of bucket elevators may very from 2 to 1000 t/h. Bucket elevators are broadly classified into two general types;

1) Spaced Bucket Elevators

The spaced-bucket centrifugal discharge type is most commonly used for elevating the grains. Bucket elevators with belts are used in food industries for vertical conveyance of grains, its derivatives and flours.

2) Continuous Bucket Elevators

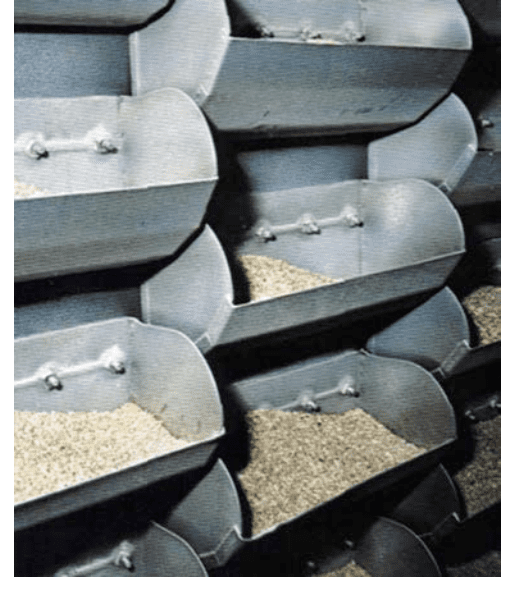

In a bucket elevator, the conveyor belt with buckets runs over pulleys at the upper and lower ends. The top pulley is driven pulley while the lower pulley is return and tension pulley. Buckets are usually made of steel or plastic and are bolted onto the belt.

The bucket elevator’s capacity mainly depends on bucket size, conveying speed, bucket design and spacing, the way of loading and unloading, the bucket and the characteristic of bulk material. Bucket elevators with a belt carrier can be used at fairly high speeds of 2.5 to 4 m/s.

Bucket elevators consist of a series of buckets attached to a belt or chain. The buckets are designed to scoop up materials and carry them to the top of the elevator, where they are discharged.

The design of the buckets and the spacing between them can vary depending on the application. Some buckets are designed for heavy-duty use, while others are more lightweight and suitable for smaller loads.

The belts or chains utilized in bucket elevators are specifically designed to endure substantial loads and high temperatures. They can be crafted from materials such as rubber, nylon, or steel, depending on the application’s requirements.

The Benefits of Lakhotia India Bucket Elevator Belt

High Efficiency

Lakhotia India’s bucket elevators are designed to be highly efficient, delivering maximum throughput with minimum energy consumption. They are engineered to move materials vertically with speed and precision, reducing the time and effort required for manual handling.

Low Maintenance

The design is simple and robust, with fewer moving parts, reducing the likelihood of breakdowns and the need for costly repairs. The use of high-quality materials also ensures durability and longevity, making them a cost-effective investment for any business.

Space Saving

bucket elevators are designed to be compact and space-saving, making them ideal for installation in areas with limited space. They are available in a range of sizes and configurations, ensuring that there is a solution to meet the needs of any application.

Bucket Elevator Belt Applications

Bucket elevators are used in a wide range of industries for the vertical transportation of materials. In the Mining industry, they are often used to transport ores and minerals from underground mines to the surface.

In agriculture, they are used to move grain, seeds, and other crops from storage facilities to processing plants.

In the food and beverage industry, bucket elevators are used to transport ingredients such as sugar, flour, and spices from one part of the production process to another. They are also used to move finished products such as snacks and cereal from the production line to packaging and distribution facilities.

Uses of Lakhotia India Bucket Elevator Belt

Our bucket elevator belts are suitable for a wide range of industrial applications, including: Bucket elevators for sale are primarily used for the vertical transportation of granular materials such as peanuts, sweets, dried fruits, rice, and pet foods, etc.

- Agriculture and food processing

- Cement manufacturing

- Mining and minerals

- Power generation

- Chemical and fertilizer production

- And much more!

Common Features of Bucket Elevators

Buckets

The buckets are the heart of bucket elevators. They are responsible for carrying the materials from one level to another. Buckets come in different shapes and sizes, depending on the material being transported. They can be made of various materials, such as plastic, steel, or aluminum.

Belt or Chain

The belt or chain is another critical component of bucket elevators. They are responsible for moving the buckets from the bottom to the top of the elevator.

The belt or chain must be strong enough to carry the weight of the buckets and the material being transported.

Drive System

The drive system is the power source that drives the belt or chain. It can be an electric motor, hydraulic motor, or pneumatic motor. The drive system must be powerful enough to move the buckets and the material being transported. It must also be reliable and easy to maintain

Head and Boot Sections

The head and boot sections are the top and bottom parts of the bucket elevator, respectively. They are responsible for supporting the belt or chain and the buckets. They must be strong and durable enough to withstand the weight of the material being transported.

The head and boot sections are the top and bottom parts of the bucket elevator, respectively. They are responsible for supporting the belt or chain and the buckets. They must be strong and durable enough to withstand the weight of the material being transported.

Safety Features

Bucket elevators can be dangerous machines if not operated and maintained properly. Therefore, they must have safety features to prevent accidents and injuries. Some of the common safety features include emergency stop buttons, safety switches, and guards.

| Bucket Elevator | Belt Conveyor |

|---|---|

| casing | belt |

| Buckets | Idlers |

| Chains | Centering Device |

| Sprockets | Drive units |

| Boot section | Bending the belt |

| Elevator frame | Conveyor frame |

Frequently Asked Questions.

What is a bucket elevator belt?

Bucket elevators are an essential part of many industrial processes, used to transport bulk materials vertically.

They are versatile machines that can handle a wide range of materials, from fine powders to large chunks of rocks.

What are the different types of bucket elevator belts?

There are various types of bucket elevator belts, such as steel cord belts, textile belts, and solid woven belts.

What factors should be considered when choosing a bucket elevator belt?

Factors such as the material being transported, the weight of the load, and the speed of the elevator should be considered when selecting a bucket elevator belt.

FOR MORE DETAILS ABOUT BUCKET ELEVATOR BELT Please feel free CONTACT US Lakhotia India Service Team