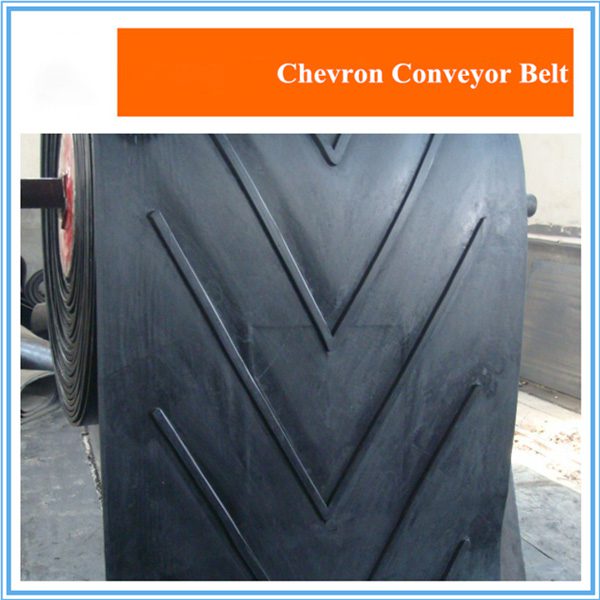

Chevron conveyor belts are designed that provide excellent grip and prevent slippage during the transportation of heavy materials. The chevron pattern can vary in height and angle, depending on the specific needs of the application.

There are two common types of chevron conveyor belt patterns:

Open V type: The open V type chevron pattern making it suitable for transporting lighter materials with a tendency to slip, such as wood chips or fine gravel.

Technical data specifications for chevron conveyor belts

Suitable for handling bulk materials or bags up to 40 degrees C, slip resistant, and big conveying capacity.

Chevron Pattern: Open V type, Closed V type, L Type, H Type, U type

Belt width

Chevron conveyor belts come in various widths, ranging from 400mm to 2200mm.

Belt thickness

The thickness of the belt can range from 4 to 30mm, depending on the application.

Chevron height

The height of the chevron pattern can range from 5 to 32mm, depending on the angle and spacing of the pattern. The biggest conveying angle can reach 28 degrees; when conveying soft packaging materials are applied, a maximum 35-degree angle can be reached.

Tensile strength

The tensile strength of the chevron conveyor belt can range from 15 to 24 Mpa OR 150 to 240 Kg/cm2.

Operating temperature

The operating temperature of the chevron conveyor belt can range from -25°C to +80°C.

Abrasion resistance

Chevron conveyor belts are designed to be highly resistant to abrasion, making them suitable for transporting heavy materials over long distances.

The belt material can vary depending on the application, with common materials including polyester, nylon, and steel cord.

Closed V type: The closed V type chevron pattern, makes it suitable for transporting heavier materials to slide, such as sand or coal.

The choice of chevron pattern type depends on the material being transported and the angle of incline of the conveyor. Different industries may have the chevron pattern type and height to ensure maximum efficiency and safety during material transport.