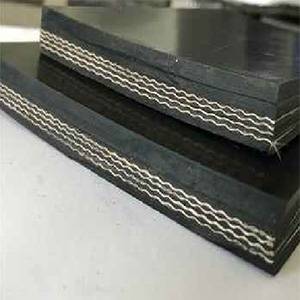

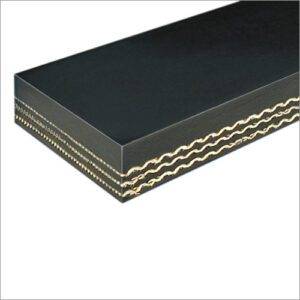

Heavy Duty Conveyor Belt (EP)

Chemical & Oil Resistance |

Antimicrobial & Safe Feature |

High and Low Temperature Resistance |

Fire Resistant |

Ep Conveyor Belt Carcass Construction Impacts The Belt Tension Ratings:

Carcass

The internal reinforcements and fabric plies provide the mechanical strength to the belt. Made up of fabrics like polyester, nylon, and cotton.

Number of Plies

More plies provide higher tensile strength to resist tension forces. Tension rating increases with more plies. 2-ply is around 400 PIW. 6-ply reaches 1200 PIW.

Ply Adhesion

Rubber coating properly bonded to fabric carcass ensures the plies work together. Poor adhesion weakens the belt strength.

Ply Thickness

Thinner but stronger fabrics allow more plies to be stacked in the same belt thickness. Increases strength without sacrificing flexibility.

Ply Orientation

Multi-ply belts with cross-oriented 0° and 90° plies provide good lateral and longitudinal stiffness. Helps under load.

Ply Material

Polyester provides the highest tensile rating per ply. Aramid fabrics offer very high strength-to-weight ratio.

Skim Coats

Skim rubber coats applied between plies help reduce internal ply friction and shear. Improves belt flexibility.

Breaker Strips

Rubber-coated fabric strips layered between plies to improve impact and flex fatigue resistance in the belt.

Belt Gauge

Total carcass thickness specified in 1/16 inch increments. More plies increase the gauge and tension rating.

Edge Sewing

The sewn fabric along belt edges helps reinforce and prevent ply separation and lifting under load.

The carcass construction and design directly influence the belt’s tension strength, capacity, and overall durability in a conveyor system.

Technical Specifications:

A ep conveyor belt is made of a blend of polyester/nylon fabric consisting of polyamide for weft and polyester for warp which makes it strong and flexible. Rubber skim coats ensure adhesion and load support, with top and bottom cover compounds for maximum protection.

Ep conveyor belts are widely used in material handling systems in manufacturing – cement, aggregate, stone crusher plant, mining, coal, and power steel industries for transporting heavy or bulky materials. They are durable, heat-resistant, and have excellent tear and abrasion resistance.

Carcass: Polyester/Nylon fabric

Width: 300 – 2400mm

Thickness: 5 – 25mm

Top cover: 1.5 – 8mm

Bottom cover: 1.5-3mm

Max. Tensile Strength: 10 – 25Mpa

Maximum Belt Speed: 3 – 4.5m/s

Cover Rubber Grade: Abrasion Resistant, Fire Resistant, Oil Resistant

Max. working temperature: 180℃

Splice Strength: 90 – 95% of the belt strength

Key Ratings And Specifications For Rubber Conveyor Belting Related to Plies:

Number of Plies

Layered fabric reinforcements inside the belt carcass. More plies increase strength and load capacity. Common ply ratings are 2, 3, 4, 5.

Ply Type

Polyester and nylon are common ep conveyor belt ply fabrics. Polyester provides greater strength while nylon offers flexibility.

Ply Strength

Measured in tension strength per ply. Rubber belts typically have 400-500 lbs per ply per inch of belt width.

Overall Belt Strength

Determined by multiplying ply rating by number of plies. A 3-ply belt with 400 lb/ply/in rating has 1,200 lbs per inch belt strength.

Tension Rating

Maximum tension force the belting can withstand repeatedly without damage. Depends on number of plies.

Load Support

More plies spread load stresses over larger area providing better load support and lengthening belt life.

Flexibility

Belts with fewer plies generally trough and flex easier around pulleys. Multi-ply belts tend to be stiffer.

Fastener Suitability

A number of plies impacts splice strength and fastener grip. Thicker belts need heavy-duty fasteners.

Carcass Gauge

Ply fabric thickness. Thinner gauge fabrics allow more plies in the same belt thickness.

EP conveyor belt Applications

Coal mining

EP conveyor belts are used to transport coal in underground mines.

Construction

M24 conveyor belts are used to transport building materials.

Cement production

Heavy-duty conveyor belts are used to transport cement and other raw materials in cement plants.

Features of EP/Nylon Conveyor Belt

High Tensile Strength

The tensile strength of EP conveyor belt is generally between 800-2500 N/mm. The higher the tensile strength, the more resistant the belt is to tearing and

abrasion.

Abrasion & Wear Resistance

They are also resistant to wear, which helps them to last for a long time. EP conveyor belts can handle a wide range of temperatures, from up to 200°C, and can be used in high-temperature environments.

Low Elongation

Lakhotia ep conveyor belts are praised for their superior strength, performance and reliability. They are highly resistant to abrasive materials and able to withstand in heavy loads

High Flexibility And Good Impact Resistance

Lakhotia India M24 grade conveyor belts are designed to have a High Impact Resistance, making them ideal for use in applications where the material being moved is Heavy and/or Sharp. They are also able to withstand extreme temperatures, making them suitable for use in extreme conditions.

Having conveyor problems? The specialists at Lakhotia India have the solutions. We troubleshoot issues, recommend fixes, and improve system efficiency. Trust us for quick repairs, optimal belting, and 24/7 support. Contact us today.