| Sales Team +91 9025194360 |

| Email Us sales@lakhotiaindia.in |

Efficiency in Motion: Powered by Motorized Pulley Conveyors

Seamless Conveyor Solutions: Harness the Strength of Motorized Pulleys

Are You Facing Problems While Usage Of Conveyor Motorized Pulley ?

Overheating

This can occur due to excessive load or inadequate cooling mechanisms. Overheating can lead to motor damage, reduced efficiency, and even system failures.

Belt slippage

Especially when there are high loads or the belt is worn or improperly tensioned. Belt slippage can result in reduced power transmission, decreased productivity, and potential damage to the equipment.

Noise and vibration

This can be caused by misalignment, unbalanced loads, worn components, or insufficient lubrication.

Maintenance and servicing

Conveyor Motorized pulleys require regular maintenance and servicing to ensure optimal performance and longevity.

This can lead to increased downtime, higher maintenance costs, and potential disruptions to the industrial process

Compatibility and customization

Industrial processes often require specific configurations and customization to meet unique requirements.

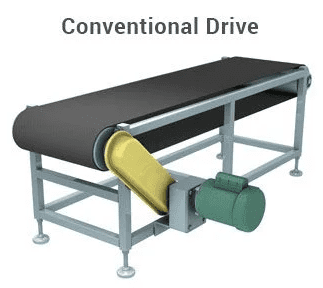

Cost

The initial cost of motorized pulleys can be higher compared to traditional drive systems, such as external motor and gearbox combinations.

Motorized pulleys can provide through energy efficiency, reduced maintenance, and improved productivity

For Serious Drum Motor Conveyor Problems, Call Lakhotia India Service Team Today!

CALL NOW

We specialize in providing top-quality services for all types of industrial drum motors diagnosis to repair and maintenance. Our experienced technicians can quickly identify and address any issues, including overheating, mechanical wear, electrical problems, contamination, and belt slippage. With our reliable and efficient services, you can minimize downtime, reduce maintenance costs, and improve productivity

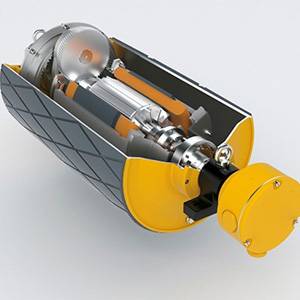

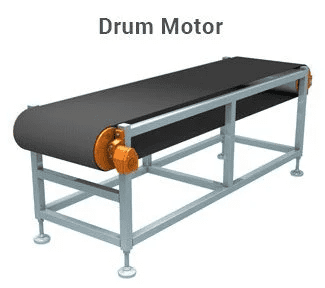

Drum Motor (Motorised Pulley)

- The Motorized Pulley (Drum Motor) is mainly used for driving conveyor belts. It is easy to install and has low running costs, minimizing maintenance. The conveyor belt pulley has been specifically designed for belt conveyors and is totally sealed, with a protection class IP 67 and a maximum power of 250kW.

- A drum motor is a one component conveyor belt drive where the motor, gear drive and all moving parts are enclosed inside the drum. Used in heavier plants for the mining industries, mobile quarries installation and in the food industry. The Conveyor Motorized pulley the ideal drive unit for conveyors “Fit it and forget it”

- A drum motor is an integrated motor and gear drive that is encased in a cylindrical shell. It is used in industrial applications such as conveyor belts, elevators, and material handling equipment.

- The motor is connected to a drum that is then attached to the conveyor belt or other moving parts. The drum motor provides a compact, efficient, and low-maintenance solution for powering industrial equipment.

Conveyor Motorized Pulley Benefits

Industrial Motorized Pulley

- Motor & Gearbox design

- Improved Safety, Thermal Protection

- Less Power & Low Noise

- Space Saving Design

- Lower Maintenance Cost

- High Efficiency & Reliability

- Hermetically sealed pulley

- Easy & Quick Installation

Standard Range of Conveyor Motorized Pulley System

| Shell diameter (mm) | Motorized pulley (Type) | Power Range (kW) |

|---|---|---|

| 138 | 138i | 0.09 – 1.0 |

| 165 | 165i | 0.15 to 2.2 |

| 216 | 220M/220H | 0.37 to 5.5 |

| 320 | 320L/320M/320H | 0.75 to 7.5 |

| 400 | 400L/400M/400H | 2.2 to 15.0 |

| 500 | 500L/500M/500H | 2.2 to 22.0 |

| 630 | 630M/630H | 5.5 to 55.0 |

| 800 | 800M/800H/800HD | 22 to 132 |

| 1000 | 1000HD | 160 to 250 |

Motorized Pulley Technical Specification

| Component | Motorized pulley includes pulley shell, bracket, coupler, motor and gear reducer. |

| Driving Power | 1.5~250 KW |

| Drum Diameter | 138 to 1000 mm |

| Belt Width | 400 to 2000 mm |

| Belt Speed | 0.35~4.5 (m/s) |

| Type conveyor | Belt Conveyor, Mobile Conveyor, Stacking Conveyor, Mobile Ship loader, etc. |

| Surface | Smooth steel surface, rubber faced, rubber lagged, ceramic lagged, diamond rubber covered |

| Standard | Quality assurance ISO9001:2008 |

| Voltage | 115V to 1000V |

| Phase | Single and three phase |

Application Of Bulk Material Handling- Drum Motors Built to Perform In Dusty and Abrasive Environments.