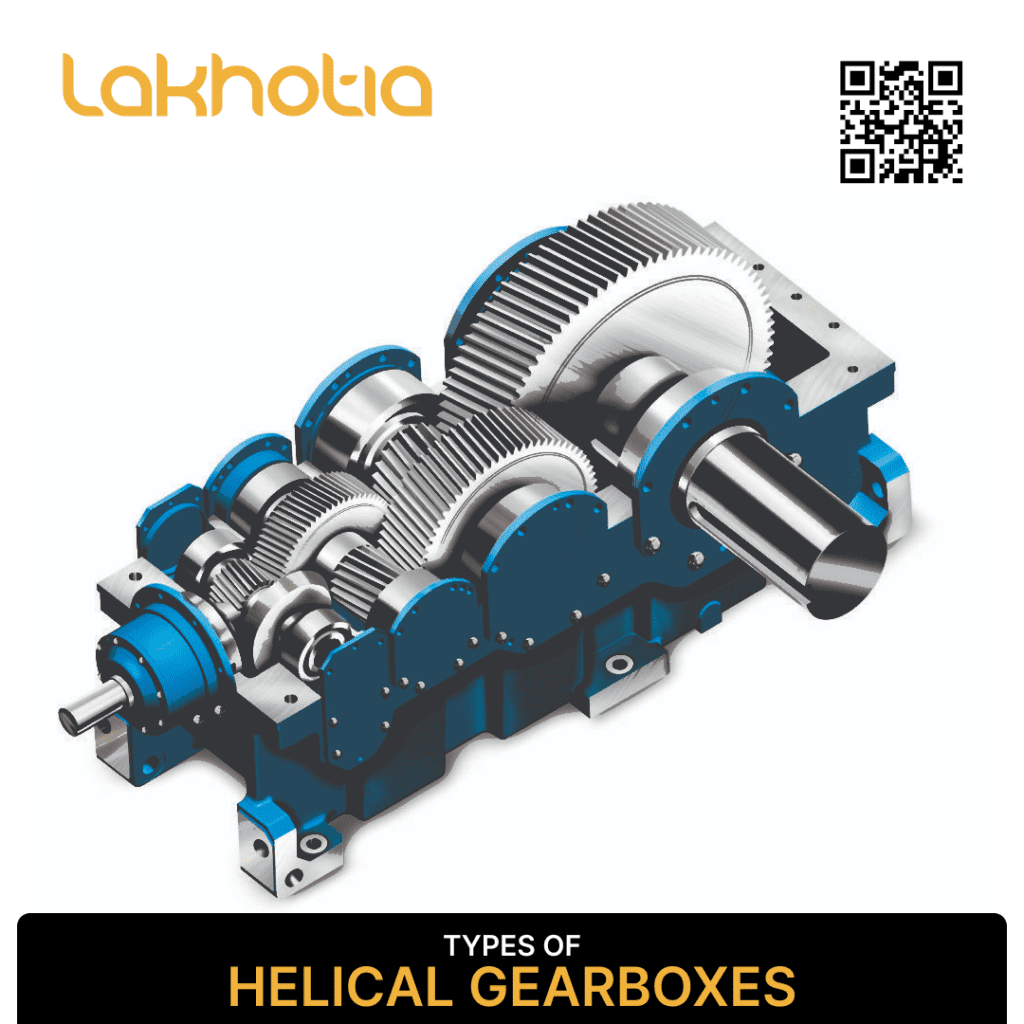

Helical gearboxes play a vital role in mechanical power transmission systems, utilizing the unique properties of helical gears to efficiently transfer motion and power between shafts. These gears are known for their angled teeth, which allow for smoother and quieter operation compared to other gear types. As a result, helical gearboxes are especially favored in high-speed applications, offering reduced noise, vibration, and improved efficiency. According to recent industry reports, the global gear market was valued at approximately USD 28.99 billion in 2022, and it is expected to experience significant growth in the coming years, primarily driven by advancements in machinery, industrial automation, and the growing demand for more efficient and reliable gear systems.

The demand for high-performance components like helical geared motors reflects the increasing reliance on advanced gear technologies in various industries, including manufacturing, automotive, robotics, and material handling. The helical gear’s design, with teeth cut at an angle to the gear face, allows for smoother meshing and greater torque transmission. This makes helical gearboxes an excellent choice for applications that require precision and durability under heavy loads and high speeds.

Helical gearboxes come in various designs, each optimized for specific industrial tasks. The versatility of helical gears allows them to be used in everything from everyday machinery to high-precision robotic systems. Below are the common types of helical gearboxes and their respective applications:

At Lakhotia, we provide the top guidance in selecting the perfect rough top conveyor belt, ensuring smooth, efficient, and reliable operation for your industrial applications. Alongside rough top belts, we offer a comprehensive range of conveyor solutions, including bucket elevator belts, heavy-duty conveyor belts, and rubber conveyor belts. As trusted suppliers in Chennai, we prioritize durability and performance in every product we offer.

1. Parallel Shaft Helical Gearboxes

Parallel shaft helical gearboxes are designed with input and output shafts placed in parallel alignment. These gearboxes are ideal for systems where parallel shaft arrangements are necessary. Their design offers the advantage of efficient power transmission with reduced wear and tear on the gears. They are commonly found in conveyor systems, industrial machinery, and material handling equipment. These applications benefit from the gearbox’s ability to provide high torque output and precision in movement. For systems that require unique specifications, custom helical gears can be designed to meet specific performance and space requirements, ensuring an optimal solution for various applications.

2. Right-Angle Helical Bevel Gearboxes

A right-angle helical bevel gearbox combines the features of helical gears with bevel gears. This design allows for a right-angle transfer, a critical feature when machinery needs to change the direction of power transmission. Right-angle helical bevel gearboxes are frequently used in conveyor systems, mixers, and other industrial machinery where space constraints require changes in direction. These gearboxes are known for their durability and ability to handle high-speed operations efficiently. Right-angle helical bevel gearboxes are essential for space-constrained applications that require high power output. For specialized needs, custom helical gears can be engineered to meet specific requirements, ensuring seamless integration with helical bevel gear motors for enhanced performance.

3. Helical Worm Gearboxes

Helical worm gearboxes combine helical gears with worm gear sets, offering a unique design that allows for high efficiency and superior torque output. These gearboxes are ideal for right-angle output situations, providing a compact and effective solution for power transmission. Widely used in conveyor systems, agitators, and other applications that require low to moderate speed operations, helical worm gearboxes are essential for industries that demand high torque and energy efficiency. Different helical gearbox types can be customized for specific applications, and custom helical gears can be designed to meet the precise performance requirements of each system.

4. Inline Helical Gearboxes

Inline helical gearboxes are similar to parallel shaft gearboxes but feature a more compact, inline design. This arrangement makes them suitable for applications where space is limited, and the gearbox needs to be mounted in a straight line with the machinery. Commonly used in pumps, conveyors, and general industrial machinery, these gearboxes offer robust power transmission capabilities without compromising on space efficiency. Inline helical gearboxes provide smooth operation and are perfect for environments requiring compact, high-efficiency components. With various helical gearbox types available, such as inline and parallel shaft options, helical bevel gear motors are often used to enhance performance, providing a reliable solution for power transmission needs.

5. Helical Planetary Gearboxes

The helical planetary gearbox combines the characteristics of helical gears with planetary gears. This design enhances torque density, precision, and compactness, making them ideal for high-efficiency applications. These gearboxes are commonly used in robotics, precision machinery, and systems requiring high efficiency and consistent performance. Their ability to manage high torque and handle demanding tasks makes them indispensable in industries such as automotive, aerospace, and industrial automation. Helical gearbox types, including the helical bevel gear motor, are designed to provide excellent torque and power transmission, ensuring smooth operation in high-performance environments.

6. Double Helical Gearboxes

Also known as herringbone gearboxes, double helical gearboxes feature two sets of helical gears that face opposite directions, helping to balance axial forces. This design provides smoother operation and greater stability under high-load conditions. These gearboxes are widely used in high-power applications, including steel rolling mills and heavy-duty industrial machinery. The elimination of axial thrust forces contributes to their enhanced durability and longevity, making them suitable for environments where power and performance are critical.

7. Inline Helical Geared Motors

Inline helical geared motors integrate helical gearboxes with electric motors, providing a compact solution for applications requiring direct motor coupling. These gearboxes are designed to fit seamlessly into machinery, eliminating the need for an external motor. Helical geared motors are used in various applications, including pumps, conveyors, and manufacturing equipment. Their ability to integrate motor and gearbox components into one unit simplifies installations, improves efficiency, and reduces operational complexity. Helical geared motors play a significant role in delivering energy-efficient solutions across many industries.

8. Helical Shaft Mounted Gearboxes

Helical shaft-mounted gearboxes are designed to be mounted directly onto the driven shaft, eliminating the need for an additional input shaft. These gearboxes are ideal for applications where space is limited or a compact solution is required. Often seen in bulk material handling systems, crushers, and conveyor systems, these gearboxes provide a simplified power transmission mechanism that reduces the complexity of installation and maintenance. Their compact design makes them versatile and efficient, providing reliable service in demanding environments. Helical gearbox types are available in various configurations, with the helical bevel gear motor being a popular choice for applications requiring smooth power transfer and efficient operation in confined spaces.

9. Customized Helical Gearboxes

Many manufacturers offer customized helical gearboxes tailored to the specific needs of a particular application. Custom gearboxes can be designed with variations in size, gear ratios, materials, and mounting configurations, allowing for a solution that meets the unique demands of each system. Whether for high-speed industrial machinery or low-torque applications, custom-designed gearboxes provide enhanced efficiency and performance. Helical gearbox types can be adjusted to fit particular requirements, and helical bevel gear motors are often included in customized solutions to improve power transmission efficiency. Customized solutions are often utilized in industries such as automotive, food processing, and material handling, ensuring that the gearbox perfectly fits the equipment and application.

Conclusion

In conclusion, helical gearboxes are indispensable in a wide range of industrial and mechanical applications. From parallel shaft helical gearboxes to customized helical gearboxes, these devices play a pivotal role in ensuring the efficient transfer of power and motion across various sectors. As industries continue to evolve, the demand for specialized gear systems like helical geared motors, helical bevel gear motors, and custom helical gears will only grow.

At Lakhotia, we are proud to be one of the top suppliers in Chennai, providing high-quality industrial solutions to a wide range of industries. We specialize in products such as bucket elevator belts, heavy-duty conveyor belts, rubber-duty conveyor belts, and EP conveyor belts. Our products are designed with precision engineering, ensuring durability, efficiency, and reliable performance in demanding environments. With years of experience and expertise, Lakhotia is committed to delivering the best conveyor solutions to meet your operational needs. We are the go-to suppliers for high-performance helical gearboxes, helical geared motors, and custom helical gears.