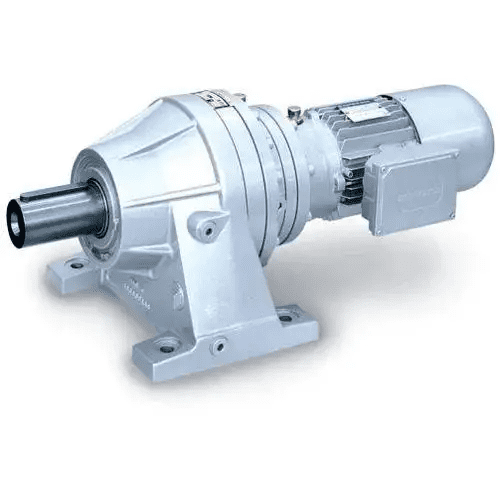

The Role of Planetary Gearmotors 300 Series in Precision Engineering

Planetary gear motors are a type of gear system used in many high-precision applications. They get their name from their unique design, which resembles a planetary system—one central gear (the sun gear) is surrounded by multiple smaller gears (planet gears) that rotate around it. This setup is encased in an outer ring gear.

Why Are They Important in Precision Engineering?

Precision engineering demands components that can offer accurate control, high efficiency, and reliable performance. Planetary gear motors, especially those in the 300 series, meet these demands due to their advanced design and superior capabilities. Here’s a deeper dive into their role:

High Precision

One of the standout features of planetary gearmotors is their ability to provide high precision in transmitting motion and power. The design of planetary gear systems ensures that motion is transferred with minimal error, allowing for precise control over speed and torque. This high precision is crucial in applications such as robotics, industrial automation, and CNC machinery, where exact movements and consistency are paramount.

Compact Size

The unique arrangement of planetary gears allows for a compact form factor. This compactness is a significant advantage in precision engineering, where space constraints and tight tolerances are common. Unlike traditional gear systems, planetary gearmotors can deliver the same level of performance in a much smaller package, making them ideal for applications where space is at a premium..

High Efficiency

Efficiency is another critical factor where planetary gear systems excel. These systems can transmit power with minimal losses, ensuring that every bit of energy is effectively used. This high efficiency is essential in precision engineering, where any loss of power can impact the overall performance and accuracy of the application. Efficient power transmission is particularly crucial in applications like industrial automation and automated warehouse systems, where consistency and reliability are key.

High Torque Density

Planetary gearmotors are renowned for their high torque density. This means they can deliver a significant amount of torque in a relatively small and compact package. High torque density is valuable in precision engineering applications that require both precise control and high power. For instance, in industrial automation and automated warehouse systems, the ability to handle high torque loads while maintaining precision is essential for optimal performance.

Smooth Operation

Smooth and stable operation is a hallmark of planetary gear systems. Even at high speeds, these gearmotors can maintain stability and reduce undesirable effects such as vibration and backlash. This smooth operation is critical in precision engineering applications, where any instability can lead to inaccuracies and inefficiencies. The ability to operate smoothly ensures that machinery and systems perform reliably and consistently.

Customization Options

The 300 series of planetary gearmotors offers a wide range of customization options, including various gear ratios, motor types, and mounting configurations. This versatility allows engineers to tailor the gearmotors to specific application requirements, ensuring optimal performance and precision. Customization is a significant advantage in precision engineering, where unique and specialized solutions are often needed to meet the demands of different applications.

Reliability and Durability

Reliability and durability are key attributes of planetary gearmotors. Thanks to their robust construction and high-quality materials, these gearmotors can withstand the rigors of demanding applications. In precision engineering, where uptime and longevity are critical, having reliable gearmotors is essential to ensure consistent performance over time. The durability of planetary gearmotors means they can operate effectively in challenging environments and maintain their performance throughout their lifespan.

Application in Industrial Automation and Automated Warehouse Systems

In industrial automation, planetary gearmotors play a key role by providing the precision and reliability needed to automate processes. The high torque density and efficient power transmission of these gearmotors make them ideal for driving machinery and equipment in automated systems.

Automated warehouse systems also benefit from the compact size and high efficiency of planetary gearmotors. These systems require precise and reliable components to ensure smooth operation and accurate handling of materials. The ability to customize planetary gearmotors to fit specific needs further enhances their value in these applications.

Conclusion

In summary, the 300 series of planetary gearmotors plays a crucial role in precision engineering by offering high precision, compact size, high efficiency, high torque density, smooth operation, customization options, reliability, and durability. These characteristics make them well-suited for a wide range of precision applications across various industries.

Whether it’s industrial automation, automated warehouse systems, or other precision engineering applications, the 300 series planetary gear motors provide the performance and reliability needed to achieve optimal results. By leveraging the unique design and capabilities of these gearmotors, engineers can ensure their systems operate with the highest level of precision and efficiency.

By considering the specific requirements of your industry and environment, ensuring the compatibility of your conveyor system components, and consulting with experts from trusted suppliers and manufacturers like Lakhotia, you can experience the unparalleled performance of the 300 series planetary gearmotors and elevate your precision engineering projects to new heights.