Industrial Geared Motors: Powering Conveyor Belt Systems

Conveyor belt systems are essential components in many industrial processes, providing an efficient means of transporting materials from one point to another. To make these systems work effectively, they require reliable and powerful motors to drive the belts. This is where industrial geared motors come in. In this article, we will explore the importance of industrial geared motors in conveyor belt systems and how they work.

What are Industrial Geared Motors?

Industrial geared motors are compact mechanical devices that transmit power to industrial machinery, such as conveyor belt systems, by reducing the motor’s speed and increasing its torque. They are designed to operate with high efficiency, durability, and reliability, making them ideal for use in heavy-duty applications.

How do Industrial Geared Motors Work in Conveyor Belt Systems?

The main function of industrial geared motors in conveyor belt systems is to drive the belts at the required speed and torque to transport materials. The motor’s power is transmitted to the gearbox, which contains gears that change the speed and torque of the motor’s output. The gearbox then drives the conveyor belt’s pulley or drive shaft, which, in turn, moves the belt.

The selection of the appropriate geared motor for a conveyor belt system depends on the specific application requirements. The factors that need to be considered include the required speed, torque, and power, as well as the size, weight, and type of materials being transported. By selecting the right geared motor for the job, conveyor belt systems can operate efficiently and reliably for extended periods.

Types of Industrial Geared Motors Used in Conveyor Belt Systems

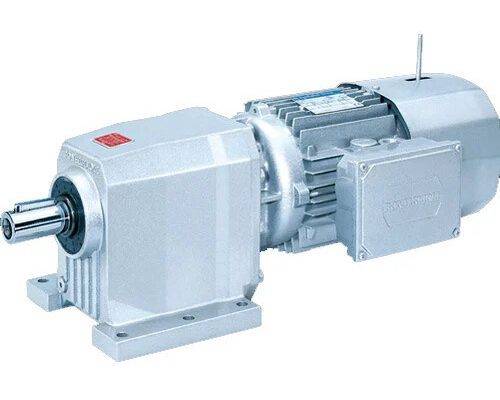

Inline Helical Geared Motors: AS series

These are the most commonly used geared motors in conveyor belt systems. They feature a set of helical gears that mesh at an angle to transmit power, providing high efficiency and low noise levels.

- Space optimized design

- Reduced installation space and wide output speed selection range

- Reduced standard backlash

- Highly dynamic, energy-saving solution

- Wide output speed selection range

- Torque Range: 50 … 12,000 Nm (442 … 106,208 in-lb)

The AS Series benefits from years of recognition in the industry and has become a best seller for quarry and mining applications, where reliability and low maintenance are key factors.

Helical Bevel Geared Motors: A series

These geared motors feature bevel gears that transmit power at an angle. They are suitable for applications that require a change of direction.

- Minimized mounting space

- Forced gears-shafts coupling

- Wide output speed selection range

- Reduced standard backlash

- High dynamic and energy saving solution

- Wide output speed selection range

- ATEX gearbox for explosive environments 2G/2D

Transmissible Mechanical Power 0.22 …150kW

Torque range 100 … 14,000 Nm

Planetary Gearmotors (300 Series)

These geared motors feature multiple gears that mesh in a planetary arrangement. They provide high torque and high efficiency, making them ideal for heavy-duty applications.

- The 300 series is compact and powerful. Their planetary drive train makes them the ideal choice for all severe duty applications where shock loads and impacts are more the rule than the exception.

- The product configuration is modular, highly versatile and offers several options for mounting and motor interface. Foot and flange mounted

- Torque range: 1,000 … 1,100,000 Nm

- Transmissible Mechanical Power up to 1,050 kW

- Improved efficiency: Industrial geared motors provide high efficiency in power transmission, resulting in reduced energy consumption and cost savings.

- Increased reliability: Industrial geared motors are designed for heavy-duty applications, making them highly reliable and durable.

- Reduced noise: Industrial geared motors operate with low noise levels, making them ideal for applications that require quiet operation.

- Flexibility: Industrial geared motors are available in various sizes and types, making them suitable for a wide range of applications.

What are the uses of industrial gearbox?

Industrial gearboxes are used in a wide range of applications across various industries. These gearboxes are designed to transmit power, speed, and torque to machinery and equipment, making them an essential component in many industrial processes.

Conveyor Systems

Industrial gearboxes are commonly used in conveyor systems, which are widely used in various industries such as mining, manufacturing, and food processing. Gearboxes provide the required power and torque to drive conveyor belts and transport materials from one point to another.

Heavy Machinery

Industrial gearboxes are used in heavy machinery such as cranes, bulldozers, and excavators. These machines require high torque and low-speed operation to move heavy loads and perform tasks such as digging and lifting. Gearboxes are used to reduce the speed of the engine output and increase the torque to provide the required power to the machinery.

Heavy Equipment Industry

Gearboxes are also widely used in the heavy equipment industry, where they provide power and speed to a range of machinery, including cranes, bulldozers, excavators, and loaders. These machines require high torque and low-speed operation to move heavy loads and perform tasks such as digging and lifting. Gearboxes are used to reduce the speed of the engine output and increase the torque to provide the required power to the machinery.

Mining Industry

Gearboxes are widely used in the mining industry, where they provide power and speed to a range of machinery, including conveyor belts, crushers, and mills. In a conveyor belt system, the gearbox is used to drive the belt and transport materials from one point to another. The gearbox also allows the operator to adjust the speed of the conveyor belt to match the production requirements.

Industrial Manufacturing Industry

Gearboxes are essential components in the industrial manufacturing industry, where they provide power and speed to a range of machinery, including pumps, compressors, and machine tools. In a pump or compressor system, the gearbox is used to drive the impeller or rotor, which generates the required pressure and flow of fluid or gas.

If you have any questions industrial geared motors related. Please Contact Lakhotia India Customer Support to get for FREE CONSULTATION.