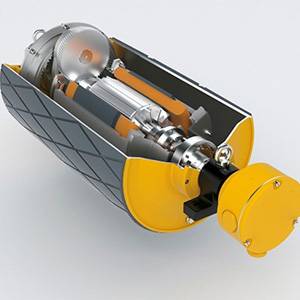

The motor is attached to a drive shaft that runs the length of the pulley and drives the outer pulley drum.

A motorized pulley has a compact, high-torque motor integrated inside the cylindrical pulley shell.

The drive shaft connects to the drum through precision machined shafts and heavy duty bearings.

As the integrated motor turns the drive shaft, the outer pulley drum rotates with it to drive the conveyor belt.

Variable frequency drives or motor controllers adjust the speed and torque of the integrated motor in response to load conditions.

Seals between the drum and end plates protect the internal motor and bearings from dust and moisture.

Sensors monitor temperature, vibration and other parameters for health monitoring and diagnostics.

The pulley essentially functions as a standard idler pulley, except it contains a sealed integrated motor providing the drive power.

This allows simplified installation and maintenance compared to external motor drives.

In summary, the integrated motor turns the sealed drum to drive the belt, while controls adjust speed and torque. This allows motorized pulleys to provide the traction and power needed for conveyor operation.

Key Considerations In The Design Of Motorized Pulleys For Conveyors:

Torque and Power

The integrated motor must provide sufficient starting and running torque for the conveyor load and speed. Determines motor size.

Pulley Diameter

Larger diameters allow greater torque transmission from the same motor. But too large adds inertia. Typical range 100-400mm.

Drum and Shaft

The drum transfers torque from the motor to the belt. The shaft connects the drum to the motor and bearings. Typically made of steel or composites.

Bearings

Sealed, heavy duty bearings like tapered roller or spherical roller bearings are used to handle radial and axial loads.

Motor Type

Compact high torque motors used include AC induction, BLDC, and brushless servo motors. AC motors work with VFDs.

Drive Method

Motors are typically direct shaft-mounted for simplest design. Some use internal planetary gears or external drives.

Seals and Protection

Rubber seals isolate internal components from dust and moisture ingress. At least IP54 rating.

Controllers

Motor controllers like VFDs and drivers allow variable speed control and optimization.

Monitoring

Sensors can track temperature, vibration and other diagnostics for health monitoring.

Safety

Emergency stop, torque limiting, overload protection should be incorporated.

The right components and sizing ensures the motorized pulley provides efficient, reliable power transmission for the conveyor belt under operating conditions.