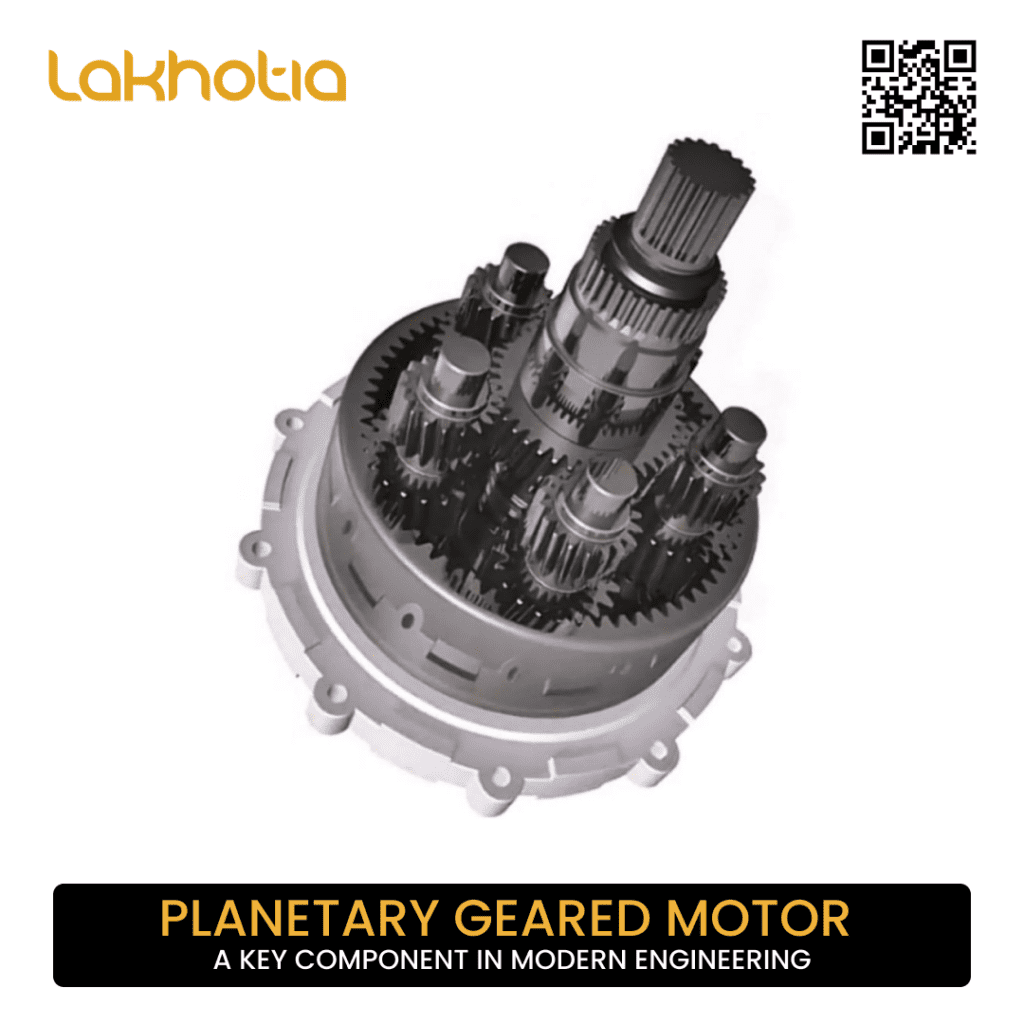

The planetary geared motor is a vital component in precision engineering, widely recognized for its efficiency, durability, and compact design. Its unique configuration enables seamless power transmission, making it indispensable in industries that demand high torque, precision, and reliability. From robotics and automation to CNC machinery, these motors serve as the backbone of numerous mechanical applications, ensuring smooth operation and long-term performance.

Industrial Planetary Gearbox: A Reliable Power Transmission Solution

It is a highly specialized mechanical component designed to ensure efficient power transmission while maintaining a compact form factor. Unlike conventional gear systems, it incorporates a sun gear, planet gears, and a ring gear, facilitating even load distribution. This design ensures smooth and efficient power transfer, making it an essential choice for demanding industrial applications.

Advantages

High Efficiency

Its superior design reduces friction and enhances mechanical output, making it a preferred solution for high-performance applications.

Compact Design

Its space-saving architecture allows seamless integration into confined spaces where traditional gear systems cannot fit. This compact design is particularly advantageous in applications where weight and size constraints are critical.

Superior Load Distribution

One of the standout features of an industrial planetary gearbox is its unique gear arrangement, which ensures uniform load distribution. This reduces wear and tear, extending the lifespan of the gearbox and enhancing its operational reliability.

High Torque Density

Due to its unique multiple-gear engagement, an industrial planetary gearbox delivers a high torque output in a smaller size. This makes it highly efficient in applications requiring powerful performance in a compact footprint.

Smooth and Quiet Operation

Planetary gear systems are known for their reduced vibration and noise levels compared to conventional gear mechanisms. This ensures smoother operation, making them ideal for precision applications like robotics, automation, and CNC machinery.

The Role of Planetary Gear Motors in Automation and Robotics

Precision and Performance

It is designed for applications requiring high precision and controlled torque output. Their low backlash characteristics make them ideal for robotics, automated assembly lines, and CNC machines, where accuracy is paramount.

Durability and Longevity

Industries demand reliability, and planetary gear motors offer long-lasting performance due to their robust construction. These motors are engineered to endure high loads and continuous operation with minimal maintenance requirements.

High Torque Output

A defining characteristic of planetary gear motors is their ability to deliver high torque while maintaining a compact size. This makes them highly suitable for industries such as industrial automation, medical equipment, and aerospace engineering.

High Torque Gear Motors: Powering Heavy-Duty Applications

Why Choose High Torque Gear Motors?

It is engineered to deliver exceptional power output while maintaining efficiency. These motors play a crucial role in industries that require significant force to move heavy loads, such as manufacturing, construction, and mining.

Industrial Applications of High Torque Gear Motors

Material Handling Systems: Ensures smooth and reliable movement of conveyor belts by utilizing a planetary geared motor for precise torque control. The industrial planetary gearbox enhances efficiency, ensuring reduced downtime and improved operational reliability.

Automotive Industry: Powers electric vehicles and hybrid systems using gear motors that provide the necessary torque and energy efficiency. These motors improve vehicle performance by offering seamless power transmission and extended battery life.

Wind Energy: Essential for turbine pitch control mechanisms, where industrial planetary gearbox solutions optimize energy conversion. The use of planetary gear motors ensures durability and precise control, making wind turbines more efficient and reliable.

Rubber Belting Suppliers: Essential for Conveyor Systems

The Importance of Quality Rubber Belts

Reliable rubber belting suppliers are essential for industries relying on conveyor systems. These suppliers provide durable, high-performance rubber belts for various applications, from mining to food processing. High-quality rubber belts ensure seamless material transport, minimizing downtime and maximizing productivity.

Industrial Applications of Rubber Belting

Mining Industry: Heavy-duty rubber belts transport minerals and raw materials, reducing manual labor and increasing operational efficiency.

Food Processing: Food-grade rubber belts ensure hygiene and safety in food handling and packaging processes.

Manufacturing: In industrial automation, rubber belts help streamline assembly lines and improve production speeds.

Agriculture: Used in machinery for grain transport and processing, rubber belting ensures durability and consistent performance.

Choosing the Right Belting Suppliers

Selecting the right belting suppliers is crucial for maintaining operational efficiency. The best suppliers offer:

High-Quality Materials for Longevity and Durability

Premium-grade rubber belts resist wear, tear, and extreme conditions, ensuring long-lasting and reliable performance.

Custom Solutions Tailored to Industry-Specific Requirements

Suppliers offer specialized rubber belts designed for mining, food processing, manufacturing, and agriculture needs.

Comprehensive Support for Installation, Maintenance, and Troubleshooting

Reliable suppliers provide expert guidance, timely repairs, and technical assistance to minimize operational downtime.

Sustainable Options for Environmentally Friendly Operations

Eco-friendly rubber belts reduce carbon footprint, support energy efficiency, and promote sustainable industrial practices.

Conclusion

The planetary geared motor remains an essential component in modern engineering, offering unmatched precision, efficiency, and compactness. As industries continue to evolve, investing in high-quality planetary gearbox solutions will ensure enhanced performance and long-term reliability. Whether in robotics, CNC machinery, or industrial automation, these advanced gear systems will continue shaping the future of mechanical power transmission.

Who is Lakhotia?

At Lakhotia, we take best service providers for planetary geared motors pride in being one of the , planetary gearboxes, and planetary gear motors. Our expertise in mechanical power transmission solutions ensures that industries receive top-quality products backed by cutting-edge technology and superior craftsmanship. We specialize in customized solutions, ensuring that our clients get optimal performance and long-term reliability from their gear systems.

With a commitment to excellence, innovation, and customer satisfaction, Lakhotia continues to be a trusted partner for businesses looking to enhance their engineering and automation processes. Choose Lakhotia for the best in gear technology solutions, ensuring your business stays ahead in a competitive industrial landscape.