Advantages of Motorized Pulley in Belt Conveyors

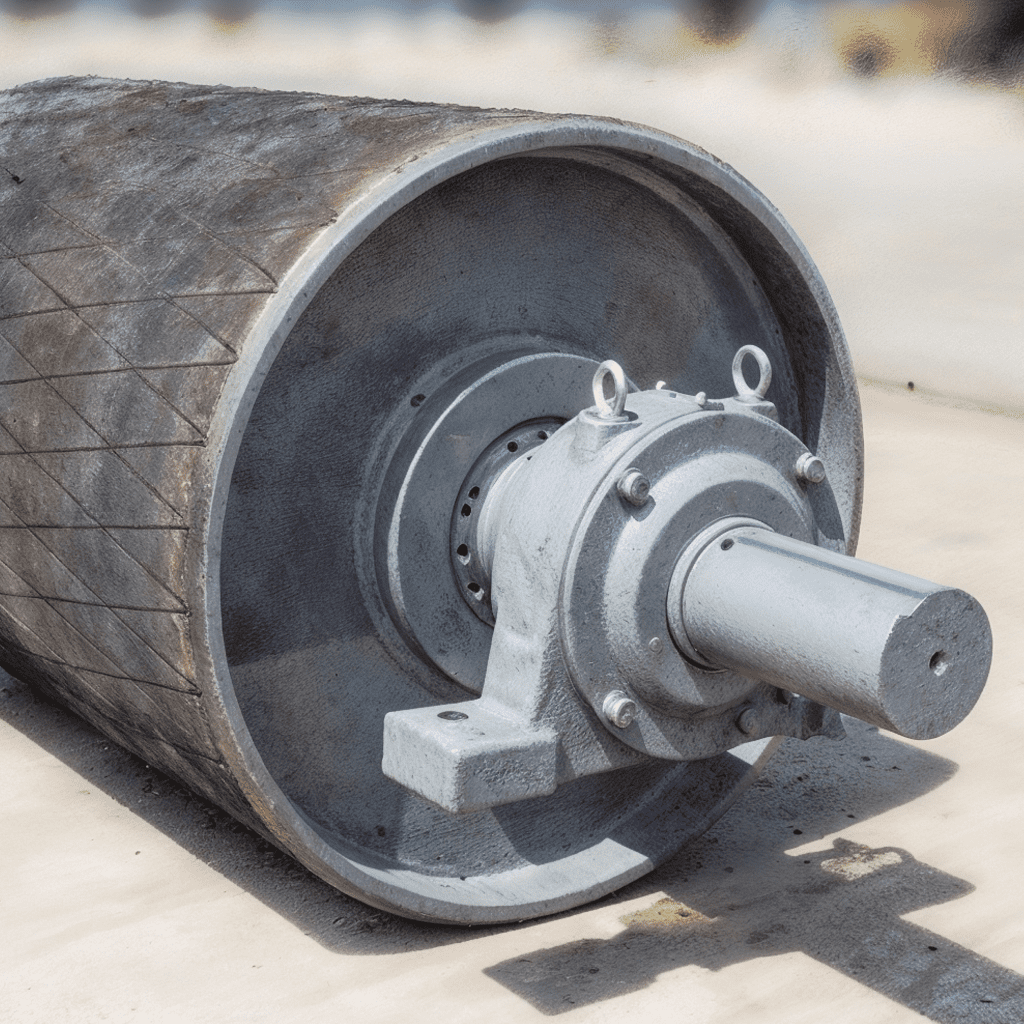

Belt conveyors are essential in industrial processes, enabling the efficient movement of materials across various applications. At the heart of these systems are pulleys, crucial components that drive and support conveyor belts. As trusted rubber conveyor belt suppliers, we understand the importance of reliable and efficient conveyor systems. Motorized pulleys, also called drum motors, have become increasingly popular due to their compact design and superior efficiency compared to traditional external drive systems. These pulleys integrate seamlessly into conveyor structures, saving space and simplifying maintenance while providing unmatched durability in demanding environments.

According to a recent MarketsandMarkets survey, the global conveyor system market is forecasted to grow from USD 10.4 billion in 2024 to USD 14.8 billion by 2030. This growth is fueled by the rising adoption of motorized pulleys, with 78% of industry professionals favoring them for their energy efficiency and minimal maintenance requirements. By understanding the various pulley types, such as motorized, drive, and tail pulleys, industries can enhance system performance and longevity. This article examines the advantages of motorized pulleys and their critical role in modernizing conveyor systems.

Space Efficiency

Motorized pulleys are compact units that integrate the motor, gearbox, and other components into a single enclosed structure. This design eliminates the need for external drive components such as gearboxes and motor mounts, offering significant space-saving advantages.

The types of pulley in conveyor belt systems influence their overall efficiency and adaptability. Motorized pulleys streamline conveyor layouts, making them ideal for installations with limited space while reducing the footprint of the conveyor system.

By replacing bulky external components, motorized pulleys enhance conveyor efficiency. Understanding the types of pulley in conveyor belt setups, including motorized options, allows industries to optimize design and operational performance effectively.

Ease of Installation

Compared to traditional external drive systems, motorized pulleys are straightforward to install. Their simplified installation process offers key benefits, particularly in terms of efficiency and ease of use.

One advantage is faster setup. Installation time can be decreased by mounting motorized pulleys directly onto the conveyor frame. This feature is especially valuable in industries where minimizing downtime is critical. Additionally, understanding the types of pulley in conveyor belt systems can further streamline installation and operational planning.

Another benefit is lower complexity. The all-in-one design of motorized pulleys minimizes the number of components required, resulting in quicker commissioning. By selecting the appropriate types of pulley in conveyor belt configurations, industries can enhance efficiency and reduce potential installation challenges.

Reduced Maintenance Requirements

Motorized pulleys are sealed units designed to protect internal components from environmental factors such as dust, moisture, and debris. Their design ensures enhanced durability, making them a reliable choice for various applications.

One key advantage is the reduced exposure to contaminants. By understanding the types of pulleys in conveyor belt systems, including motorized pulleys,supplier industries can select options that minimize wear and tear, extending equipment lifespan. This results in lower maintenance requirements and improved performance.

Additionally, motorized pulleys lower maintenance costs. With fewer exposed parts compared to traditional systems, they require less frequent servicing. Selecting the appropriate types of pulley in conveyor belt setups can further optimize maintenance strategies.

Energy Efficiency

Modern conveyor systems must take energy efficiency into account.. Motorized pulleys play a significant role by offering direct power transmission, which minimizes energy losses commonly seen in traditional systems. They have an advantage in many applications because of this benefit.

One of the key benefits is cost savings. By improving energy efficiency, motorized pulleys help reduce operating expenses over time. In setups involving a tail pulley belt conveyor this efficiency ensures consistent performance while lowering energy consumption.

Furthermore, the integration of a tail pulley belt conveyor with motorized pulleys enhances system reliability. The optimized energy use and reduced losses contribute to sustainable and cost-effective operations.

Quiet Operation

The enclosed design of motorized pulleys significantly contributes to quieter conveyor operation, making them an ideal choice for various industrial applications. When selecting the right Types of pulley in conveyor belt for your system, consider the benefits of motorized pulleys.

Reduced noise levels and improved workplace conditions are just a few advantages, creating a more comfortable and productive environment for operators. This is particularly important in indoor or noise-sensitive areas where quieter conveyors can make a significant difference.

Understanding the different Types of pulley in conveyor belt is crucial in optimizing conveyor performance. By choosing the right pulley for your application, you can ensure a smoother, quieter, and more efficient conveyor operation that meets your specific needs and requirements.

Improved Safety

Safety is a top priority in industrial settings, and motorized pulleys play a significant role in enhancing safety protocols. Motorized pulleys reduce the chance of mistakes and injury through decreasing exposed parts. This is particularly important in applications where a Tail pulley belt conveyor is used, as it can help prevent entanglements and other hazards.

The sealed design of motorized pulleys also simplifies maintenance tasks, lowering the risk of mishaps during routine upkeep. This design feature is especially beneficial in environments where a Tail pulley belt conveyor is utilized, as it reduces the likelihood of maintenance-related accidents.

By incorporating motorized pulleys into your industrial setup, you can significantly improve safety and reduce the risk of accidents. All employees may benefit from a safer workplace, more productivity, and reduced downtime as the result.

Variable Speed Control

Many motorized pulleys are equipped with variable speed control options, offering unparalleled flexibility and customization. This feature enables operators to adjust conveyor speed to match specific material handling requirements, ensuring that the conveyor system operates at peak efficiency. This level of control is particularly valuable in industrial conveyor systems where precision and adaptability are essential for optimizing performance and productivity.

The benefits of variable speed control are numerous, particularly in applications where precision and control are crucial. In systems featuring a Tail pulley belt conveyor variable speed control can be especially valuable, allowing operators to fine-tune conveyor speed and optimize performance.

By incorporating motorized pulleys with variable speed control into your conveyor system, you can unlock new levels of efficiency, productivity, and flexibility. This feature is particularly valuable in industrial conveyor systems where precision and adaptability are essential for optimizing performance and productivity. Additionally, this feature is also beneficial in applications where conveyor speed must be adjusted frequently, such as in material handling or packaging operations.

Cleaner Environment

The sealed construction of motorized pulleys helps maintain a cleaner workplace, which is essential in various industries. As experienced rubber conveyor belt suppliers, we recognize the importance of minimizing contamination risks in sensitive applications. By containing lubricants and other contaminants within the unit, motorized pulleys reduce the risk of product contamination.

In industrial conveyor systems, cleaner conveyor systems are crucial for maintaining high standards of hygiene and quality. This is particularly important in industries such as food processing and pharmaceuticals, where contamination can have serious consequences.

By incorporating motorized pulleys into industrial conveyor systems, businesses can ensure a cleaner and more hygienic operation. This not only helps to prevent contamination but also reduces the risk of costly downtime and maintenance.

Longer Conveyor Belt Lifespan

Motorized pulleys offer a distinct advantage in industrial conveyor systems by operating at lower belt tensions compared to external drives. This design feature leads to reduced wear on the conveyor belt.

The benefits of lower belt tension are numerous. Reduced wear minimizes stress on the conveyor belt, extending its lifespan. This, in turn, leads to cost savings as longer-lasting belts reduce replacement and maintenance expenses.

By incorporating motorized pulleys into industrial conveyor systems, businesses can reap the rewards of reduced maintenance and extended conveyor belt lifespan. This results in increased uptime, improved productivity, and lower overall operating costs.

Adaptability to Harsh Environments

Motorized pulleys are engineered to withstand challenging operating conditions, making them suitable for a variety of industries. Their adaptability includes resistance to extreme temperatures, allowing them to perform reliably in both hot and cold environments.

The durability of motorized pulleys makes them an ideal choice for handling abrasive materials, often paired with rubber conveyor belt material. They excel in mining, agriculture, and manufacturing applications where harsh conditions are common.

When combined with rubber conveyor belt material, motorized pulleys provide a reliable and efficient conveying solution. Their ability to withstand challenging conditions ensures optimal performance, reduced downtime, and increased productivity in demanding industrial environments.

Customization Options

Motorized pulleys can be tailored to meet specific application needs, ensuring optimal performance and efficiency. As a key component, the conveyor belt pulley is designed to work seamlessly with the motorized pulley, providing a reliable and efficient conveying solution. Varied sizes and power ratings are available to suit a range of conveyor capacities and requirements.

When paired with rubber conveyor belt material, motorized pulleys provide a reliable and efficient conveying solution. Customization options, such as specialized coatings, can enhance the durability and performance of the conveyor system.

By selecting the right motorized pulley and rubber conveyor belt material for your application, you can ensure a tailored solution that meets your specific needs. As a result, production grows, downtime decreases, and overall efficiency grows.

Conclusion

Motorized pulleys represent a reliable, efficient, and user-friendly solution for belt conveyor systems. Their compact design, ease of installation, reduced maintenance needs, and adaptability to harsh environments make them an excellent choice for various industrial applications. When paired with rubber conveyor belt material motorized pulleys provide a durable and efficient conveying solution.

The benefits of motorized pulleys are numerous. By improving energy efficiency, safety, and operational flexibility, motorized pulleys contribute to increased productivity, reduced downtime, and a better overall working environment. As a crucial component of conveyor systems, the conveyor belt pulley plays a vital role in ensuring smooth operations. They are an excellent choice for areas that need dependable and effective conveyor systems because they are made for using demanding applications.Lakhotia’s expertise as a leading rubber conveyor belt supplier enables us to offer a comprehensive range of products, including Heat resistant conveyor belts,EP conveyor belts, and Heavy duty conveyor belts, as well as Bucket elevator belts. Our motorized pulleys, paired with these high-quality belts, provide a reliable and efficient conveying solution for various industrial applications. By adopting Lakhotia’s motorized pulleys, businesses can optimize their conveyor systems, leading to increased productivity and cost savings.